Inside Nichels Engineering |

In July 1966, an extensive series of photos were taken at Nichels Engineering documenting the buildup and preparation of Chrysler's factory stock car fleet. Ray Nichels built this facility on Main Street, Griffith Indiana in 1965 after securing the Chrysler car building contract. Nichels was the authorized builder and distributor of Chrysler stock cars and parts from 1964 through 1970. What you see remained similar all the way through the aero car era. Ray still maintained his original shop on Cline Ave., a few miles away in Highland. The Nichels facility here in Griffith, contained 41,000 sq. feet for manufacturing, with an additional 3,200 sq. ft for offices. On the side you see here, this was the car preparation side where race prep and maintenance was done. The brick rooms off to the right were for machine shop, drive train buildup, led to the two engine dyno rooms. Below in the race prep shop, looking towards the rear of the building, you can see work taking place on Don White's Charger with the right door off, up on the jack. Paul Goldsmith's Plymouth is in the back. The purpose of the plain white wrapper Dodge in the foreground is unknown. It could very well have been a company car. Interesting things in the background are the car hauler; and just over the back of the hauler is a Don White pit board with the message "$$" on it. No doubt that Don won the race. Also, what looks like a drivers ice chest on the workbench to the left front of the Charger. Behind the tires in the back is a large storage room for Chrysler race parts inventory. |

Here, more interesting stuff on the wall by the brick rooms: A four wheel car dolly, a stock fuel tank, and miscellaneous hood and decklid inner bracings that are discards. To the left of the parts, note the oversize man door to get large things in/out to the main shop. There are garage doors on both ends of the building to allow the car hauler to drive right on through. |

A nice photo from out in front of the building. That's Paul Goldsmith's year old 1965 Plymouth must be idling away with the crew under the hood. The awning at the left of the photo is the main entrance, and the administrative offices are to the left of the garage door. Later on, the building had an good size addition put on to the left of the photo for projects and development to be kept out of the eyes of the general shop. The addition area is where Ray later operated Nichels Automotive Products until he passed away. At that time, Kathy Krieter, Ray's secretary of over 40 years still answered the phone same as it was in 1966. |

Moving on to the machine shop and mechanical buildup areas: A rack of 8 ¾ Chrysler rear ends housings are in process of modification for circle track competition. On the wheeled cart behind, are stacks of Hemi connecting rods. All the way in back on the shelves are an assortment used Hemi pistons in the boxes as marked, and more rods and new pistons on the shelves to the right. Wow! |

The four wheel shop cart with pistons and crank is shown to the right of the rear end rack from the previous page. More pistons and rods on the wall behind. Seems like an endless supply of parts. |

One of my favorite photos is the one below showing the cylinder head assembly. There's lots to see in the photo. Don't you just love the July 1966 pinup calendar? Just to the right of that is a newspaper clipping talking about the introduction of the new 1966 Charger from the Chicago Tribune. Next to the "Service Engineering" tips is a USAC newsletter or racing paper with the 1966 race schedule displayed. Boxes of used valves, some good, some marked as "shot" are below the workbench. The man working in the photo is Nichels employee Bill Beadle. |

Here, we're inside the engine assembly area. Below, at left is Minnie Joyce, and on the right with the measuring tool is Hank Heyen. Comments below from Nichels book author Bill LaDow. "Minnie joined Nichels in 1962 and stayed through the early 1970's When AJ Foyt drove Chryslers ... he demanded that Minnie and only Minnie, worked on his engines. In fact Minnie Joyce blueprinted every Hemi that was shipped by Chrysler, thru Nichels, for Stock Car racing during 1964 thru 1970. The Hemi explosion in 1964 was under the direction of Minnie Joyce ... in the upcoming Ray Nichels book, you will read that the guy who made the first restrictor plate was Minnie Joyce . Once the plates were tested by Glotzbach and Goldsmith late in 1969, they were given to Bill France, Sr. It is no coincidence that the first race won by a restrictor plate was Glotzbach in the Nichels Engineering Dow Dodge Daytona Charger at Michigan in 1970." |

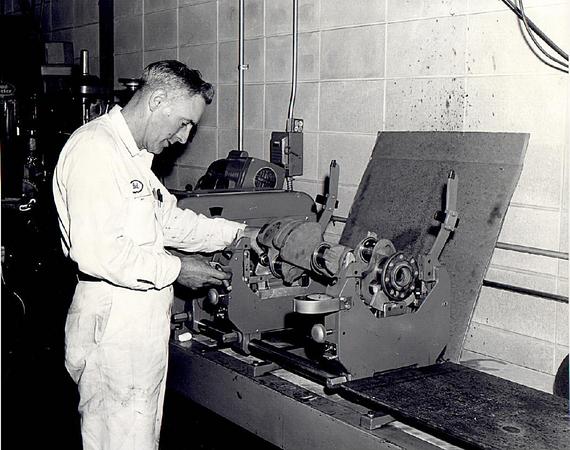

In this photo, working on the Hemi crankshaft, cigar in hand, is Nichels mechanic Bud May. |

What a sight! Seven blueprinted race Hemi engines are ready for shipment to Chrysler teams. I noticed that one group of them have black valve covers and the others are Hemi Orange. I don't know if that means anything. They all have the Mopar gold oil filters on them which are big money NOS items today! At the time Nichels has two engine dynos in the building. The Griffith Indiana shop has 41,000 square feet, and in the wintertime, the entire building was filled to the gills with parts, engines and cars. They used to hang race car bodies and body parts from the ceiling to gain space. |

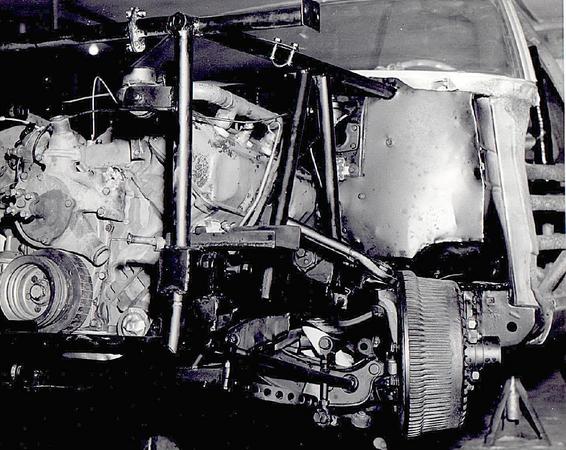

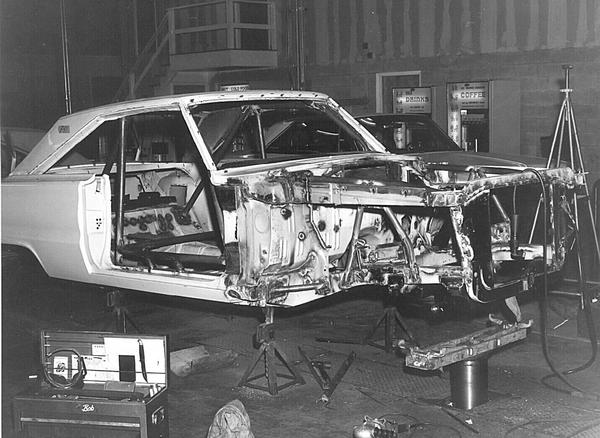

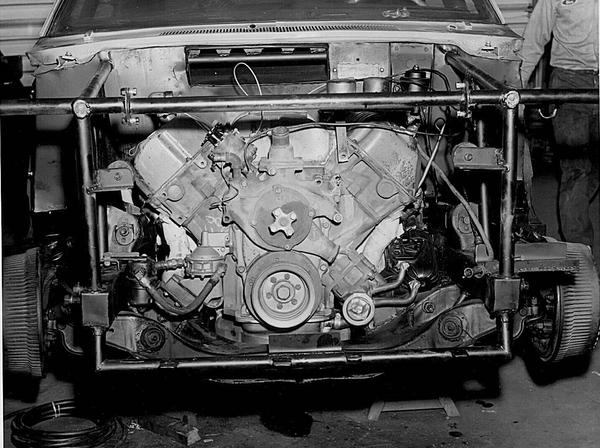

At left is a later photo dated from 1969, showing a used race car back at Nichels for repair after some on-track skirmish. Some people continue to refer to how "stock" these cars of the time were. Compared to a modern NASCAR stock car, which is more like a cartoon character compared to anything Detroit sells, that I'd agree with that statement that way. But looking back, while it is true that the basic unibody architecture of the mid 1960's car is similar to the street car with torsion bar suspension, there is not a lot of "stock" left in these cars. Just about everything else was purpose built even then. I remember Larry Rathgeb telling a story about how in 1963, when Chrysler was just getting ready to really "go racing", that he was directed by boss Ronny Householder to take Nichels Pontiac stock car suspension pieces and adapt them to the Plymouth and Dodges. Those didn't work well, and Chrysler had to engineer and develop their own pieces as 1964 rolled along. If you look at the photo, you can see some Chrysler street car in the front lower frame rail and the cams for the upper control arm mount. The lower control arm is a heavily reinforced piece. The front sway bar is a race only piece, as are the super heavy duty spindle, brake assembly and drum. The upper structure is all tube frame and tied in with the roll cage in the interior. The upper radiator support tube can be unbolted to ease engine removal and installation. The firewall has been fabricated of sheet metal, and there is a single brake master cylinder. The engine crossmember, or K frame as it's known, is also a race only fabricated piece and looks nothing like the street car. Transmission tunnels were widened and hand fabricated. Next we'll go over to the car fabrication shop and show you some more photos of cars in the build-up process. . |

Here are some nice photos as we move into the fabrication and car build shop. Above: Paul Goldsmith's '65 Plymouth is at left. Note all the different fabrication templates and patterns hung on the wall. To the right of the '65 Plymouth is a new '66 Plymouth shell being converted to NASCAR specification. |

Above is a continuation of the shop moving from left to right. In fact you can splice these two photos together for a better view. Don White's Charger is on the high work stands, and another body in white '66 sits in the foreground, ready for conversion to race duty. As we work through the photo sequence, it looks to me as the left car under construction was actually an assembly line body with parts stripped off it, compared to the body in white in the front which never had any trim or glass on it. |

Don White's Charger on the high stands for some front end work between races. As you can see, in 1966, the cars still had a basically stock firewall with a reinforcement brace running from the lower cowl over to the frame rail. Front sway bar is a special fabricated piece. The car is still using a stock radiator support. You cannot see it here, but there is an upper tube under the top of the fender running lengthwise to the radiator support. Now, compare this to the photo below, shot in 1969. A big change in that all you really recognize as "stock" appearing are the lower frame rails. Up top, you can see the tubing I just mentioned running forward on each side of the firewall to the completely fabricated radiator support. And again, the center of the rad support is removeable to make engine swaps easier and faster. The firewall is also completely fabricated. |

Here again is a better photo of the '66 Plymouth under construction from the first page of the article. The Nichels serial number P41 is written on 2" wide tape on the roof pillar. This car as mentioned before. must have been much farther along the assembly line, or possibly even complete when pulled as it has glass clips, and evidence that the drip rail trim and goo from the windshield trim being removed. It even has production radiator blackout paint. Follow the shock towers up on the driver side and you can see the reinforcements. Although the body is heavily reinforced throughout the car, we still have minimal roll cage side bars. When did NIchels stop building race cars from complete factory produced production cars? Nichels used to strip down complete cars at the original shop in Highland (1964 and 1965 seasons). So cars for Bobby Isaac, Joe Leonard, Len Sutton, Paul Goldsmith, AJ Foyt were all tear downs. Chrysler was having cars built at four locations during this time and ending in 1966. The three locations Bill has confirmed were Nichels, Norm Nelson' Automotive, and Cotton Owens Garage. The earliest "body in white" car with photo documentation, is Sam McQuagg's 1966 NASCAR Charger at the Go-Fast Factory in Griffith. |

Above are thirty-eight race Hemi engines. At a conservative $25,000 each today, that would be nearly a million dollars of inventory today. We hope you have enjoyed your trip to Nichels Engineering and down memory lane. |