1 of 1 Prototype Charger Race Hood |

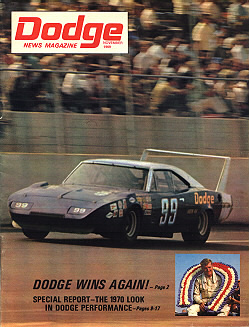

If you have ever seen the Daytona sales brochure that was sent out to Dodge dealers in early 1969, you will remember it was an artist rendering. Mainly because the development of the car had not been finalized. One of the features shown on the car was a recessed NACA hood scoop, similar to what was released on the 69 & 70 Shelby Mustang hoods. NACA, was the National Advisory Committee for Aeronautics; the forerunner of what became NASA. The purpose of a NACA duct is maximum airflow with low or no drag penalty. NACA ducts date back to the late 1940's, when they were top secret stuff. Today, they are mounted on every race car. In late 1969, Dodge News published photos of the white mockup Daytona shown on the five mile oval at the Chrysler Proving Grounds. Check out the article in Dodge news which alludes to the upcoming Daytona having a NACA scoop |

This car was the white Charger cobbled into a Daytona for the photo shoot. It had no rear window plug, no A-pillar mouldings, and the fiberglass nose had no headlight openings, and black tape was used to simulate them and did so convincingly. Styling people had used clay and quick dry lacquer to make a good ten foot example. Chrysler Engineer John Pointer has told a story about how the night before the photo shoot, he shut the mocked up hood after everyone had left for the night and was horrified to find that the leading edge of the hood would not meet the nose! Much scurrying around and frantic phone calls to recall people solved the problem, and the photo shoot went off okay. |

Meanwhile, back at the race track, in October 1969, Charger 500 race chassis 046 was being probed and prodded with different air induction techniques. Several configurations of air induction were attempted by the Huntsville Alabama based Woodward Garage development team. Then as now, the carburetor takes its air from the high pressure area at the base of the windshield. The race air cleaner is fastened right to to firewall and takes air from the cowl. Base line airflow measurements were taken in stock configuration. Then, a rather crude looking "mailbox" ram air scoop was then added over the top of the cowl. Lastly, a recessed NACA scoop was fabricated into the forward third of a metal '69 Charger race hood. Neat stuff. |

One of the reasons the factory race development team had a shop in Huntsville Alabama was the access to people like John Vaughn and Bill Wright, Both John and Bill worked at Chrysler's Huntsville Operations, or the Space Division, and became involved with the race program in early 1968. What they brought to the table were things like wind tunnel experience , and instrumentation know-how, needed to do the laboratory portions of the development of the Charger 500 and Daytona. In addition, Bill Wright was instrumental in improving the on-board data acquisition of the full scale race cars on track. In 1968, the Huntsville Operations involvement with the Saturn rocket program was mostly over with so those people were looking for things to do. In April of 1968, Huntsville Operations made a lengthly and detailed proposal to Chrysler's home office Engineering department back in Highland Park, to let them organize and develop a test program for automotive aerodynamic testing. A small group of guys reporting to Bill Wright at Huntsville would be created. In concept, Huntsville Operations proposed they could illustrate tested and proven component designs so stylists could interpret aerodynamic effect due to styling changes and what was optimum - and shape future designs accordingly, versus attempting to fix a bad aerodynamic design later on. Well, we know that won't work since styling and engineering don't work that well together. But it was a nice idea! Reading between the lines, the objective was to get the funding and approval from Highland Park to improve the race cars. On the next page are excerpts from Chrysler engineer John Vaughan and Bill Wright's memo on what happened testing the NACA hood. I have removed some of the engineering mumbo-jumbo so you won't get lost. In reality, since this testing was done in late 1969, the Daytonas were already out on the street. The NACA hood never made it onto the Daytona for one reason , since it was not included on the production car. But the memo provides an interesting look at what might have been. Below is a transcript of the memo: |

AUTOMOBILE HOOD SCOOPS AND COWL SCOOP TESTS During the week of August 17 1969, Engineering Car No. 046, a race version of the 1968 Dodge Charger 500, was taken to Talladega International Speedway for the purpose of collecting data for the purpose of evaluating hood and cowl scoops used for inducting carburetor inlet air. Two basic configurations were tested. The first configuration utilized the normal air intake source in the car cowl area to feed the carburetor, while the second configuration used a specifically designed hood scoop (called a N.A.C.A. inlet) to obtain carburetor air. Modifications to configuration 1 were made by the addition of several sized deflectors (1 ½", 1 ¾", 3 ½") mounted over the standard cowl intake as shown in figure 2. Analysis of the first series of test data show it to be highly erratic in most areas with no definite trends apparent. The second series of tests indicate a more stable measurement. However, few positive conclusions can be drawn in regard to duct efficiencies since great aerodynamic flow differences exist between the Charger 500 and the Charger Daytona. An attempt was made to collect the data at the same engine RPM values for each condition, but due to the configuration differences, track and wind conditions, the carburetor throttle position was not always the same. During an earlier test series on the Charger Daytona where the 3.5 inch cowl inlet scoop was used, the engine exhaust pipe color showed a significant change during a brief 1 ½ lap run at Daytona. Since carburetor air/fuel ratio characteristically goes leaner as air density increases, some indication of carburetor inlet pressure change, if signficant, could be observed through the plug analysis. With this in mind, Wide Open Throttle plug checks were made on the NACA inlet and on the optimum cowl inlet. These plugs were sent to the Engineering Office for evaluation. However, to date, no results have been received regarding these plug checks. Significant gains in engine horsepower can be achieved through proper ducting of air to and through the carburetor. Development of ducting should be ideally performed under more controllable conditions, such as the engine laboratory in proportion with properly controlled wind tunnel tests. It is extremely important in such tests to be able to investigate the entire system and not just an engine or a duct. Aerodynamic flow of a system such as an automobile can be significantly affected by engine air flow characteristics, carburetor ducting, and location of inlet on the body and ducting. All must be optimized within the given constraints if any significant improvement is to be gained. All subsystems must be thoroughly understood either analytically or empirically in order to design follow-on body-engine system ducting. These track tests were extremely limited in instrumentation and a vehicle restricted to 160 MPH due to poor mechanical conditions, and absence of a clean aerodynamic front end (not standard Charger 500). From this experience, it is felt that with a reasonably good aerodynamic vehicle, good instrumentation (now available at a nominal cost) and careful test planning and preparation, we can obtain positive high speed results at the track to supplement wind tunnel tests and/or dynamometer testing. These types of tests performed in parallel with regular race car performance tests on a non-interference basis can be achieved at nominal or mininum costs. John Vaughn for W.P. Wright |

The Chrysler memo is somewhat inconclusive as to the effect of the scoop because of the variables that could not be controlled during the track test. But it does say that gains could be made with proper ducting and that more testing should be performed. In the words of Bill Wright in 2001, "It converted velocity pressure to positive at the carburetor. It worked!" Below are some more recent photos of original test hood mockup. It still exists how nice to see it didn't get scrapped. |

Here are a couple of photos of the hood as it exists today. We owe thanks to Bill Wright for having the foresight to save such a neat piece of history. |

Above is a photo of the underside of the hood. It is pure race spec, with none of the underbody bracing you would see on a street car. |